Introduction

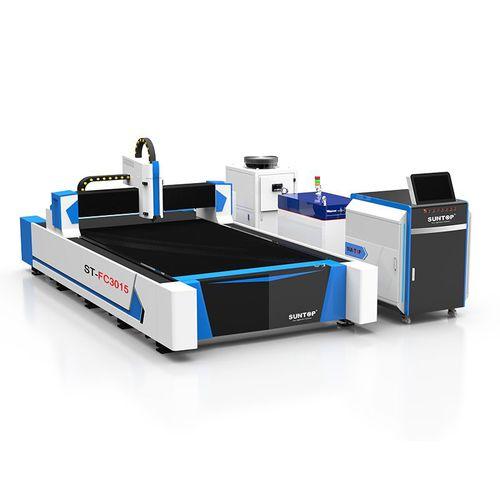

Fiberlaserisanewtypeoffiberlaserthatisnewlydevelopedintheworld.Itoutputshigh-energy-densitylaserbeam,whichisconcentratedonthesurfaceoftheworkpiece,sothattheworkpieceiscoveredbyanultra-finefocusspot.Theirradiatedareainstantlymeltsandvaporizes,andtheirradiatedpositionofthelightspotismovedbytheCNCmechanicalsystemtorealizeautomaticcutting.Comparedwithbulkygaslasersandsolid-statelasers,ithasobviousadvantagesandhasgraduallydevelopedintoanimportantcandidateinthefieldsofhigh-precisionlaserprocessing,lidarsystems,spacetechnology,andlasermedicine.

Thefiberlasercuttingmachinecanbeusedforplanecuttingorbevelcutting,andtheedgesareneatandsmooth.Itissuitableforhigh-precisioncuttingprocessingsuchasmetalplates.Atthesametime,itcanbeusedwithamechanicalarm.Three-dimensionalcuttingreplacestheoriginallyimportedfive-axislaser.Comparedwiththeordinarycarbondioxidelasercuttingmachine,itsavesmorespaceandgasconsumption,andhasahighphotoelectricconversionrate.Itisanewenergy-savingandenvironmentally-friendlyproduct,anditisalsooneoftheworld'sleadingtechnologicalproducts.

TheadvantagesoffiberlasercuttingmachineoverCO2lasercuttingmachine:

1)Excellentbeamquality:smallerfocusedspot,finercuttinglines,higherworkefficiency,andprocessingqualityBetter;

2)Extremelyhighcuttingspeed:2timesthatofthesamepowerCO2lasercuttingmachine;

3)Extremelyhighstability:usingtheworld'stopimportedopticalfiberThelaserhasstableperformance,andtheservicelifeofkeycomponentscanreach100,000hours;

4)Veryhighelectro-opticalconversionefficiency:Theopticalfiberlasercuttingmachinehasaphotoelectricconversionefficiencyofabout30%,whichis3timeshigherthanthatofaCO2lasercuttingmachine.Times,energysavingandenvironmentalprotection;

5)Verylowusecost:Thepowerconsumptionofthewholemachineisonly20-30%ofthesamekindofCO2lasercuttingmachine;

6)VerylowMaintenancecost:nolaserworkinggas;opticalfibertransmission,noreflectivelens;cansavealotofmaintenancecosts;

7)easyproductoperationandmaintenance:opticalfibertransmission,noneedtoadjusttheopticalpath;

8)Superflexiblelightguideeffect:smallsize,compactstructure,easytoflexibleprocessingrequirements.

Ofcourse,comparedwithcarbondioxidelasercuttingmachine,thecuttingrangeofopticalfiberisrelativelynarrow.Becauseofthewavelength,itcanonlycutmetalmaterials,andnon-metalsarenoteasilyabsorbedbyit,whichaffectsitscuttingrange.

TheadvantagescomparedwithYAGlasercuttingmachine:

1)Cuttingspeed:Thespeedoffiberlasercuttingmachineis4-5timesthatofYAG,suitableformassprocessingandproduction

2)Costofuse:ThecostofusingfiberlasercuttingmachineislessthanthatofYAGsolidlasercutting.

3)Photoelectricconversionefficiency:Thephotoelectricconversionefficiencyoffiberlasercuttingmachineis10ofYAGThepriceofthecorrespondingfiberlaserishigher,sothepriceoffiberlasercuttingmachineismuchhigherthanthatofYAGlasercuttingmachine,butitismuchlowerthancarbondioxidelasercuttingmachine.Butitssexratioisindeedthehighestofthethree.

Mainfeatures

(1)Thefiberlaserhashighelectrical-to-opticalconversionefficiency,withaconversionefficiencyofmorethan30%.Thelow-powerfiberlaserdoesnotneedtobeequippedwithachiller.Itisair-cooledandcanbelargeItsavespowerconsumptionduringwork,savesoperatingcosts,andachievesthehighestproductionefficiency;

(2)Whenthelaserisrunning,onlyelectricenergyisrequired,andnoextragasisrequiredtogeneratethelaser,whichhasthelowestoperatingandmaintenancecosts.;

(3)Fiberlaseradoptssemiconductormodularandredundantdesign,noopticallensintheresonantcavity,nostart-uptime,noadjustment,nomaintenance,andhighstabilityadvantages,reducingaccessoriesThecostandmaintenancetimeareunmatchedbytraditionallasers;

(4)Theoutputwavelengthoffiberlaseris1.064microns,whichis1/10oftheCO2wavelength,andtheoutputbeamqualityisgood,andthepowerdensityishigh.,Itisveryconducivetotheabsorptionofmetalmaterials,andhasexcellentcuttingandweldingcapabilities,sothattheprocessingcostisthelowest;

(5)Thelightofthewholemachineistransmittedbyopticalfiber,andthereisnoneedforcomplicatedlightguidessuchasmirrors.Thesystemhasasimpleopticalpath,stablestructure,andmaintenance-freeexternalopticalpath;

(6)Thecuttingheadcontainsaprotectivelens,whichreducestheconsumptionofexpensiveconsumablessuchasfocusinglens;

(7)Thelightisexportedthroughtheopticalfiber,whichmakesthedesignofthemechanicalsystemverysimple,anditisveryeasytointegratewiththerobotormulti-dimensionalworkbench;

(8)Thelasercanbemulti-machineafteraddingtheshutter.,Throughopticalfibersplitting,itisdividedintomultiplechannelstoworkatthesametime,easytoexpandthefunction,convenientandsimpletoupgrade;

(9)Thefiberlaserissmallinsize,lightinweight,movableinworkingposition,andsmallinfootprint;

Industryapplications

Appliedtosheetmetalprocessing,aviation,aerospace,electronics,electricalappliances,subwayaccessories,automobiles,foodmachinery,textilemachinery,engineeringmachinery,precisionparts,ships,metallurgyEquipment,elevators,householdappliances,craftgifts,toolprocessing,decoration,advertising,metalprocessing,kitchenwareprocessingandothermanufacturingandprocessingindustries.

Processingmaterials

Stainlesssteel,carbonsteel,alloysteel,siliconsteel,springsteel,aluminum,aluminumalloy,galvanizedsheet,galvanizedsheet,picklingsheet,copper,silver,Gold,titaniumandothermetalplatesandpipecutting.

Processingadvantages

(1)Highprecision,fastspeed,narrowcuttingseam,minimumheat-affectedzone,smoothcuttingsurfacewithoutburrs.

(2)Thelasercuttingheadwillnottouchthesurfaceofthematerialandwillnotscratchtheworkpiece.

(3)Theslitisthenarrowest,theheat-affectedzoneisthesmallest,thelocaldeformationoftheworkpieceisminimal,andthereisnomechanicaldeformation.

(4)Goodprocessingflexibility,canprocessarbitrarygraphics,andcanalsocutpipesandotherprofiles.

(5)Itcancutanyhardnessmaterialssuchassteelplate,stainlesssteel,aluminumalloyplate,cementedcarbide,etc.withoutdeformation.

Selectioncriteria

Thequalityoflasercuttingcanbemeasuredbythefollowing6criteria.

1.CuttingsurfaceroughnessRz

2.Cuttingslagsize

3.Cuttingedgeperpendicularityandslopeu

4.Cuttingedgefilletsizer

5.Dragafterstripen

6.FlatnessF

Cuttingadvantage

1.Highcuttingaccuracy:thepositioningaccuracyofthelasercuttingmachineis0.05mm,andtherepeatpositioningaccuracyis0.03mm.

2.Thelasercuttingmachinehasanarrowslit:thelaserbeamisfocusedintoasmallspot,sothatthefocalpointcanreachahighpowerdensity.Thematerialisquicklyheatedtothedegreeofvaporizationandevaporatestoformahole.Withtherelativelinearmovementofthelightbeamandthematerial,theholecontinuouslyformsaslitwithaverynarrowwidth.Thewidthoftheslitisgenerally0.10-0.20mm.

3.Thecuttingsurfaceofthelasercuttingmachineissmooth:thecuttingsurfacehasnoburrs,andthesurfaceroughnessofthecutisgenerallycontrolledwithinRa6.5.

4.Thelasercuttingmachineisfast:thecuttingspeedcanreach10m/min,andthemaximumpositioningspeedcanreach30m/min.Itismuchfasterthanthewirecuttingspeed.

5.Thelasercuttingmachinehasgoodcuttingquality:non-contactcutting,thecuttingedgeislittleaffectedbyheat,thereisbasicallynothermaldeformationoftheworkpiece,andthecollapseofthematerialformedduringpunchingandshearingiscompletelyavoided.Generally,thecuttingseamdoesnotrequiretwoSub-processing.

6.Nodamagetotheworkpiece:Thelasercuttingheadwillnotcontactthesurfaceofthematerialtoensurethatitdoesnotscratchtheworkpiece.

7.Notaffectedbytheshapeoftheworkpiece:laserprocessinghasgoodflexibility,canprocessanygraphics,andcancutpipesandotherprofiles.

8.Thelasercuttingmachinecancutavarietyofmaterials:suchasplastic,wood,PVCleather,textiles,plexiglass,etc.

9.Savemoldinvestment:Laserprocessingdoesnotrequiremolds,nomoldconsumption,nomoldrepairs,andsavingtimeformoldreplacement,therebysavingprocessingcostsandreducingproductioncosts,especiallysuitableforprocessinglargeproducts.

10.Materialsaving:Usingcomputerprogramming,productsofdifferentshapescanbecuttomaximizetheutilizationofmaterials.

11.Improvethespeedofsampledelivery:Aftertheproductdrawingisformed,laserprocessingcanbeperformedimmediately,andthephysicalobjectofthenewproductcanbeobtainedintheshortesttime.

12.Safetyandenvironmentalprotection:Laserprocessinghaslesswaste,lownoise,clean,safe,andpollution-free,whichgreatlyimprovestheworkingenvironment.

Technicalparameters

Devicemodel | |

Lasertype | Fiberlaser |

Laserworkingmedium | YVO4 |

laserwavelength | 1064nm |

Ratedoutputpower | 2000W |

Beamquality | <0.373mrad |

Effectivecuttingrange | 3000×1500mm |

Axialpositioningaccuracyofworktable | ≤±0.0mm/m |

Repeatpositioningaccuracyofworktable | ≤±0.0mm |

Maximumloadcapacityofworktable | 800KG |

Powerdemand | 380V/50Hz/100A |

Opticalfiberadvantage

FiberlasercuttingmachineusesfiberlasertoproduceThelasercuttingmachinewiththelightsourceasthelightsource.

TheadvantagesoffiberlasercuttingmachineoverCO2lasercuttingmachine:

1)Excellentbeamquality:smallerfocusedspot,finercuttinglines,higherworkefficiency,andprocessingqualityBetter;

2)Extremelyhighcuttingspeed:2timesthatofthesamepowerCO2lasercuttingmachine;

3)Extremelyhighstability:usingtheworld'stopimportedopticalfiberLaser,stableperformance.

4)Veryhighelectro-opticalconversionefficiency,energysavingandenvironmentalprotection;

5)Verylowcostofuse:thepowerconsumptionofthewholemachineislowerthanthatofco2,Savedproductioncosts

6)Verylowmaintenancecosts:nolaserworkinggas;opticalfibertransmission,noreflectivelenses;cansavealotofmaintenancecosts;

7)productoperationandmaintenanceareconvenient:Opticalfibertransmission,noneedtoadjustthelightpath;

8)Superflexiblelightguideeffect:smallsize,compactstructure,easytoflexibleprocessingrequirements.ThefiberlasercuttingmachineadoptstheuniquedesignofGermantechnologyandspecialinnercavitytoensurethestableoperationofthesystemandtheconstantandlastingpower.Thecuttinggapisuniform,anditisconvenienttoadjustthelightandmaintain.Theenclosedlightpathguideslighttoensurethecleanlinessandservicelifeofthelens.

Fiberlasercuttingmachinehashighcuttingprecision,whichissuitableforcuttingprecisionpartsandfinecuttingofvariouscraftcharactersandpaintings.Thecuttingspeedisfast,whichismorethan100timesthatofwirecutting.Theareaofheat-affectedareaissmall,theperformanceisstable,continuousproductionisguaranteed,itisnoteasytobedeformed,thecuttingseamissmoothandbeautiful,andthereisnoneedforsubsequentprocessing.ComparedwiththeCNCpunchingmachine,thefiberlasercuttingmachinecancompletetheprocessingofvariouscomplexstructures.Aslongasanyimagecanbedrawnonthecomputer,themachinecancompletetheprocessing.Thereisnoneedtoopenthemold,justmakethedrawingonthecomputer,andtheproductcanbereleasedimmediately.Itcanquicklydevelopnewproductsandsavecosts.ThecomplexprocessrequirementsaredifficulttoachievewithCNCpunches,andfiberlasercuttingmachinescandoit.

Inaddition,thesurfacecutbythefiberlasercuttingmachineisverysmooth,whichisdifficultforCNCpunchingmachinestoreach.Fiberlasercuttingmachinesarewidelyusedinadvertisingsignproduction,sheetmetalstructure,highandlowvoltageelectricalcabinetproduction,textilemachineryparts,kitchenutensils,automobiles,machinery,elevators,electricalparts,springs,subwaypartsandotherindustries.

Intermsofprice,fiberlasercuttingmachineisslightlymoreexpensivethanordinarylasercuttingmachine,butfromanoverallpointofview,fiberlasercuttingmachineisthemostcost-effective.

Useandmaintenance

Howtouseandmaintainthefiberlasercuttingmachine?Whenusingafiberlasercuttingmachinetoprocessobjects,itisnecessarytolearntheequipmentuseandmaintenanceskillsofthefiberlasercuttingmachineinordertobetterexerttheefficiencyoftheequipmentandmaximizetheefficiencyoftheequipment.

Howtouseandmaintainthefiberlasercuttingmachine:

1)Checkthesteelbeltfrequentlytoensurethatitistight.Otherwise,ifthereisaprobleminoperation,itmayhurtpeople,orevencausedeathinseriouscases.Thesteelbeltlookslikeasmallthing,buttheproblemisstillabitserious.

2)Checkthestraightnessofthetrackandtheverticalityofthemachineeverysixmonths,andifitisfoundtobeabnormal,itwillbemaintainedanddebuggedintime.Ifthisisnotdone,thecuttingeffectmaynotbesogood,theerrorwillincrease,andthecuttingqualitywillbeaffected.Thisisthetoppriorityandmustbedone.

3)Useavacuumcleanertoremovedustanddirtfromthemachineonceaweek.Allelectricalcabinetsshouldbeclosedanddust-proof.

4)Theguiderailsshouldbecleanedfrequentlytoremovedustandotherdebristoensurethattheequipmentisnormal.Therackshouldbewipedfrequentlyandlubricatedtoensurelubricationwithoutdebris.Theguiderailshouldbecleanedandlubricatedfrequently,andthemotorshouldalsobecleanedandlubricatedfrequently.Themachinecanmovebetterandcutmoreaccurately,andthequalityofthecutproductswillbeimproved..

5)Thedual-focuslasercuttingheadisafragileitemonthelasercuttingmachine.Long-termusewillcausedamagetothelasercuttinghead.

Fiberlasercuttingmachineneedsregularinspectionandmaintenance.Ifthereisanydeformationorotherforms,youshouldknowthatthelasercuttingheadisabitdamagedatthistimeandneedstobereplaced.Failuretoreplaceitwillaffectthecuttingqualityandincreasethecost.Someproductsmayhavetoundergosecondaryprocessingandreduceproductionefficiency.ThelasercuttingheadmustbemanufacturedbyHuagongFaril,anditmustbecarefullycheckedwhenthegoodsarereceived,soastoavoidproblemswhentheyareused.

Custombeam

Thecustombeamshapeinthefiberlasercuttingmachineisbasedonaprinciple,thatis:Comparedwiththetraditionallasercuttingusingasinglecircularlaserbeam,thenewcuttingprocessAcomplexlaserbeamshapeisused.Theuniquefocusingcharacteristicsofhigh-powersingle-modefiberlasersareusedtogeneratecomplexbeamshapesandmakeitpossibletoseparateapartoftheoveralllaserenergyinordertocreatea"keyhole"forlaserweldingorlasercuttingapplications.Therestoftheenergywillbedistributedtothemelt;beforethat,themainbeamisusedtocreateanappropriatelyhighvaporpressuredistributiononthesurfaceofthemoltenmaterial.Thismakesitpossibletoapplylocalpressureonthemeltflowingoutoftheincision,whichfarexceedsthepressureofthecoaxialgasjetcommonlyusedinlasercutting.Asaresult,theincisionisverynarrow.Thenewprocesshasgreatpotential.Itwillnotproduceburrsinalargecuttingspeedrange,andcanalsoperformhigh-speedcuttinginnarrowcontourcuttingtoproducehigh-qualitycuts.

Rapidprototyping

TherapidprototypingtechnologyinthefiberlasercuttingmachineisthegeneraltermfortherapidproductionofsamplesorpartsdirectlybasedontheCADmodel.ItintegratesmodernscientificandtechnologicalachievementssuchasCADtechnology,numericalcontroltechnology,lasertechnologyandmaterialtechnology,andisanimportantpartofadvancedmanufacturingtechnology.Itcanautomatically,directly,quicklyandaccuratelymaterializedesignideasintoprototypeswithcertainfunctionsordirectlymanufacturepartsaccordingtoCADmodels(electronicmodels),andgeneratealmostarbitrarilycomplexpartswithoutusingmoldsandtools.Theproblemofrapiddockingfromdesigntomanufacturing.Therefore,thetechnologycanquicklyevaluateandmodifyproductdesign,effectivelyshortentheproductdevelopmentcycle,reducedevelopmentcosts,andmeettherequirementsoftoday'shighlycompetitivemarketforrapiddevelopmentandrapidmanufacturingofnewproducts,andimproveThemarketcompetitivenessofproductsandthecomprehensivecompetitivenessofenterprises.

Waterchiller

Asasupportingcoolingdeviceforfiberlasercuttingmachine,waterchillerensuresthatthefiberlasercuttingmachineoperatesnormallyataconstanttemperature.Thespecialchillerforfiberlasercuttingmachineisarefrigeratedindustrialchiller.Ithastwoworkingmodes:constanttemperatureandintelligenttemperatureadjustment,andthetemperaturecontrolaccuracyis±0.3℃.Theconfigurationisrich,includingtheinputandoutputcontrolequipmentswitchandtheadvancedfunctionsofcoolingwaterflow,highandlowtemperaturealarm,stableanddurableperformance,andparticularlyexcellentinenergysavingandenvironmentalprotection.

Technicalparameters:

One-stopautomaticintelligenttemperaturecontrol:Indifferentenvironments,userscanautomaticallyswitchtotheappropriatecontroltemperaturewithoutchanging;

CW-6100AT:Itcanbeusedtocoolasingle300W-1000Wfiberlaser.

Equippedwithheaterandpurifiedwaterconfiguration.

Model | CW-6100AT | CW-6100BT |

Workingvoltage | AC1P220V | AC1P220V |

Workingfrequency | 50Hz | 60Hz |

Workingcurrent p> | 1~6.5A | |

Compressorpower | 1.38KW | 1.29KW |

1.84HP | 1.72HP | |

Refrigerationcapacity | 930Btu/h+13640Btu/h | 930Btu/h+12958Btu/h |

0.3KW+4KW | 0.3KW+3.8KW | |

180Kcal/h+3440Kcal/h | 180Kcal/h+3268Kcal/h | |

refrigerant | R-22/R-410a | |

Chargeamount | 950g | 900g |

Temperaturecontrolaccuracy | ±0.5℃ | |

Throttle | Capillary | |

Safetyprotection | Compressorover-currentprotection,flowalarm,over-temperaturealarm | |

Waterpumppower | 0.1KW+0.55KW | |

Watertankcapacity | 4L+12L | |

Inletandoutlet | Rp1/2"+Rp1/2" | |

Maximumhead | 25M+28M | |

Maxflowrate | 16L/min+58L/min | |

Netweight | 65Kgs | |

Grossweight | 75Kgs | |

Machinesize | 60X47X89cm(lengthXwidthXheight) | |

Packagesize | 74X60X109cm(lengthXwidthXheight) |

Precautionsforuse:

1,Pleasemakesurethatthepowersocketisingoodcontactandthegroundwireisreliablygrounded!

2,pleaseensurethattheworkingvoltageofthechillerisstableandnormal!

Becausetherefrigerationcompressorismoresensitivetothepowersupplyvoltage,thenormalworkingvoltageofourcompany'sstandardproductsis200~250V(110Vmodelis100~130V).Ifyoureallyneedawideroperatingvoltagerange,youcancustomizeitseparately.

3.Mismatchedpowerfrequencywillcausedamagetothemachine!

Pleaseusethe50Hzor60Hzmodelaccordingtotheactualsituation.

4.Toprotectthecirculatingwaterpump,itisstrictlyforbiddentorunwithoutwater!

Thewaterstoragetankhasbeenemptiedbeforethenewmachineispacked.Pleasemakesurethatthewatertankisfilledwithwaterbeforeturningiton,otherwisethewaterpumpiseasilydamaged.Whenthewaterlevelofthewatertankisbelowthegreen(NORMAL)rangeofthewaterlevelgauge,thecoolingcapacityofthechillerwillslightlydecrease.Pleaseensurethatthewaterlevelofthewatertankiswithinthegreen(NORMAL)rangeofthewaterlevelgauge.Itisstrictlyforbiddentousethecirculatingpumptodrainwater!

5.Pleaseensurethattheairinletandoutletchannelsofthechilleraresmooth!

Theairoutletonthechillermustbeatleast1250pxawayfromtheobstacle,andtheairinletonthesidemustbeatleast500pxawayfromtheobstacle.

6.Thefilteroftheairinletmustbecleanedregularly!

Thedustscreenmustberemovedandcleanedregularly.Seriousblockageofthedustscreenwillcausethechillertomalfunction.

7.Pleasepayattentiontotheinfluenceofcondensationwater!

Whenthewatertemperatureislowerthantheambienttemperatureandtheambienthumidityishigh,condensedwaterwillbegeneratedonthesurfaceofthecirculatingwaterpipeandthecooleddevice.Whentheabovesituationoccurs,itisrecommendedtoincreasethewatertemperatureorheatthewaterpipeandthecooleddevice.

8.Thisproductisindustrialequipment,pleasedonotletnon-professionalsoperateit.

Impact

Withtherapidexpansionofsheetmetalprocessingtechnology,domesticprocessingtechnologyisalsomovingatarapidpace,andthegapwithforeigncountriesisgettingsmallerandsmaller.Manywell-knownforeigncompanieshaveThemanufacturingbasewastransferredtoChina,andthefiberlasercuttingmachinealsobroughtmanyreactionaryconceptstosheetmetalprocessing.

Lasercuttingmachineisatechnologicalrevolutioninsheetmetalprocessing,anditisthe"processingcenter"insheetmetalprocessing;lasercuttingmachinehasahighlevelofflexibility,fastcuttingspeed,highconsumptionefficiency,andshortproductconsumptioncycle,Towinthegeneralmarketforcustomers.Thelasercuttingmachinehasnocuttingforceandnodeformationinprocessing;notoolwearandgooddatacompliance;nomattersimpleorcomplexparts,itcanbecutwithlaserprecisionandrapidformingatonetime;itscuttinggapisnarrow,cuttingqualityisgood,andthelevelofautomationishigh.Theoperationissimple,thelaborintensityislow,andthereisnopollution;itcancompletecuttingandautomaticnestingandnesting,whichimprovesthedataapplicationrate,lowconsumptioncost,andgoodeconomicefficiency.Thetechnologyhasalongeffectivelifespan.Atpresent,fiberlasercuttingmachinesaremostlyadoptedforsheetswithathicknessofmorethan2MMinforeigncountries.Manyforeignexpertsanalyzethatthenext30-40yearswillbethegoldenperiodoflaserprocessingtechnologyexpansion(thedirectionofsheetmetalprocessingexpansion)).