Въведение

Фибролазерisanewtypeoffiberlaserthatisnewlydevelopedintheworld.Itoutputshigh-energy-densitylaserbeam,whichisconcentratedonthesurfaceoftheworkpiece,sothattheworkpieceiscoveredbyanultra-finefocusspot.Theirradiatedareainstantlymeltsandvaporizes,andtheirradiatedpositionofthelightspotismovedbytheCNCmechanicalsystemtorealizeautomaticcutting.Comparedwithbulkygaslasersandsolid-statelasers,ithasobviousadvantagesandhasgraduallydevelopedintoanimportantcandidateinthefieldsofhigh-precisionlaserprocessing,lidarsystems,spacetechnology,andlasermedicine.

Thefiberlasercuttingmachinecanbeusedforplanecuttingorbevelcutting,andtheedgesareneatandsmooth.Itissuitableforhigh-precisioncuttingprocessingsuchasmetalplates.Atthesametime,itcanbeusedwithamechanicalarm.Three-dimensionalcuttingreplacestheoriginallyimportedfive-axislaser.Comparedwiththeordinarycarbondioxidelasercuttingmachine,itsavesmorespaceandgasconsumption,andhasahighphotoelectricconversionrate.Itisanewenergy-savingandenvironmentally-friendlyproduct,anditisalsooneoftheworld'sleadingtechnologicalproducts.

TheadvantagesoffiberlasercuttingmachineoverCO2lasercuttingmachine:

1) Отлично качество на лъча: по-малко фокусирано място, по-фини линии на рязане, по-висока ефективност на работа и по-добро качество на обработка;

2)Extremelyhighcuttingspeed:2timesthatofthesamepowerCO2lasercuttingmachine;

3)Extremelyhighstability:usingtheworld'stopimportedopticalfiberThelaserhasstableperformance,andtheservicelifeofkeycomponentscanreach100,000hours;

4)Veryhighelectro-opticalconversionefficiency:Theopticalfiberlasercuttingmachinehasaphotoelectricconversionefficiencyofabout30%,whichis3timeshigherthanthatofaCO2lasercuttingmachine.Times,energysavingandenvironmentalprotection;

5)Verylowusecost:Thepowerconsumptionofthewholemachineisonly20-30%ofthesamekindofCO2lasercuttingmachine;

6) Много ниски разходи за поддръжка: без работещ с лазер газ; предаване на оптични влакна, без отразяваща леща; може да спести много разходи за поддръжка;

7)easyproductoperationandmaintenance:opticalfibertransmission,noneedtoadjusttheopticalpath;

8) Свръхгъвкав световоден ефект: малък размер, компактна структура, лесни за гъвкави изисквания за обработка.

Ofcourse,comparedwithcarbondioxidelasercuttingmachine,thecuttingrangeofopticalfiberisrelativelynarrow.Becauseofthewavelength,itcanonlycutmetalmaterials,andnon-metalsarenoteasilyabsorbedbyit,whichaffectsitscuttingrange.

Предимствата в сравнение с машината за лазерно рязане YAG:

1)Cuttingspeed:Thespeedoffiberlasercuttingmachineis4-5timesthatofYAG,suitableformassprocessingandproduction

2)Costofuse:ThecostofusingfiberlasercuttingmachineislessthanthatofYAGsolidlasercutting.

3)Photoelectricconversionefficiency:Thephotoelectricconversionefficiencyoffiberlasercuttingmachineis10ofYAGThepriceofthecorrespondingfiberlaserishigher,sothepriceoffiberlasercuttingmachineismuchhigherthanthatofYAGlasercuttingmachine,butitismuchlowerthancarbondioxidelasercuttingmachine.Butitssexratioisindeedthehighestofthethree.

Основните функции

(1)Thefiberlaserhashighelectrical-to-opticalconversionefficiency,withaconversionefficiencyofmorethan30%.Thelow-powerfiberlaserdoesnotneedtobeequippedwithachiller.Itisair-cooledandcanbelargeItsavespowerconsumptionduringwork,savesoperatingcosts,andachievesthehighestproductionefficiency;

(2)Whenthelaserisrunning,onlyelectricenergyisrequired,andnoextragasisrequiredtogeneratethelaser,whichhasthelowestoperatingandmaintenancecosts.;

(3)Фибролазерadoptssemiconductormodularandredundantdesign,noopticallensintheresonantcavity,nostart-uptime,noadjustment,nomaintenance,andhighstabilityadvantages,reducingaccessoriesThecostandmaintenancetimeareunmatchedbytraditionallasers;

(4)Theoutputwavelengthoffiberlaseris1.064microns,whichis1/10oftheCO2wavelength,andtheoutputbeamqualityisgood,andthepowerdensityishigh.,Itisveryconducivetotheabsorptionofmetalmaterials,andhasexcellentcuttingandweldingcapabilities,sothattheprocessingcostisthelowest;

(5)Thelightofthewholemachineistransmittedbyopticalfiber,andthereisnoneedforcomplicatedlightguidessuchasmirrors.Thesystemhasasimpleopticalpath,stablestructure,andmaintenance-freeexternalopticalpath;

(6)Thecuttingheadcontainsaprotectivelens,whichreducestheconsumptionofexpensiveconsumablessuchasfocusinglens;

(7)Thelightisexportedthroughtheopticalfiber,whichmakesthedesignofthemechanicalsystemverysimple,anditisveryeasytointegratewiththerobotormulti-dimensionalworkbench;

(8)Thelasercanbemulti-machineafteraddingtheshutter.,Throughopticalfibersplitting,itisdividedintomultiplechannelstoworkatthesametime,easytoexpandthefunction,convenientandsimpletoupgrade;

(9) Влакнестият лазер е с малък размер, лек, подвижен в работна позиция и малък отпечатък;

Индустриални приложения

Прилага се за обработка на ламарина, авиация, космическо пространство, електроника, електрически уреди, аксесоари за метрото, автомобили, хранителни машини, текстилни машини, инженерни машини, прецизни части, кораби, металургия, оборудване, асансьори, домакински уреди, занаятчийски подаръци, обработка на инструменти, декорация, реклама, обработка на метали, обработка на кухненски пръстени и кухненски съдове и прибори

Материали за обработка

Неръждаема стомана, въглеродна стомана, легирана стомана, силиконова стомана, пружинна стомана, алуминий, алуминиева сплав, поцинкована ламарина, поцинкована ламарина, лист за ецване, мед, сребро, злато, титан и други термометални плочи и рязане на тръби.

Предимства на обработката

(1) Висока прецизност, бърза скорост, тесен режещ шев, минимална зона на топлинно влияние, гладка режеща повърхност без неравности.

(2)Thelasercuttingheadwillnottouchthesurfaceofthematerialandwillnotscratchtheworkpiece.

(3)Theslitisthenarrowest,theheat-affectedzoneisthesmallest,thelocaldeformationoftheworkpieceisminimal,andthereisnomechanicaldeformation.

(4)Goodprocessingflexibility,canprocessarbitrarygraphics,andcanalsocutpipesandotherprofiles.

(5) Може да реже всякакви материали с твърдост като стоманена плоча, неръждаема стомана, алуминиева сплавна плоча, циментиран карбид и др. без деформация.

Критерии за подбор

Thequalityoflasercuttingcanbemeasuredbythefollowing6criteria.

1.Грапавост на повърхността на рязанеRz

2.Изрезкиразмер на шлаката

3. Перпендикулярност и наклон на режещия ръб

4. Авангарден филетайзер

5.Dragafterstripen

6.ПлоскостF

Предимство при рязане

1. Висока точност на рязане: точността на позициониране на лазерната машина за рязане е 0,05 mm, а точността на многократно позициониране е 0,03 mm.

2.Thelasercuttingmachinehasanarrowslit:thelaserbeamisfocusedintoasmallspot,sothatthefocalpointcanreachahighpowerdensity.Thematerialisquicklyheatedtothedegreeofvaporizationandevaporatestoformahole.Withtherelativelinearmovementofthelightbeamandthematerial,theholecontinuouslyformsaslitwithaverynarrowwidth.Thewidthoftheslitisgenerally0.10-0.20mm.

3.Thecuttingsurfaceofthelasercuttingmachineissmooth:thecuttingsurfacehasnoburrs,andthesurfaceroughnessofthecutisgenerallycontrolledwithinRa6.5.

4.Thelasercuttingmachineisfast:thecuttingspeedcanreach10m/min,andthemaximumpositioningspeedcanreach30m/min.Itismuchfasterthanthewirecuttingspeed.

5.Thelasercuttingmachinehasgoodcuttingquality:non-contactcutting,thecuttingedgeislittleaffectedbyheat,thereisbasicallynothermaldeformationoftheworkpiece,andthecollapseofthematerialformedduringpunchingandshearingiscompletelyavoided.Generally,thecuttingseamdoesnotrequiretwoSub-processing.

6.Nodamagetotheworkpiece:Thelasercuttingheadwillnotcontactthesurfaceofthematerialtoensurethatitdoesnotscratchtheworkpiece.

7.Notaffectedbytheshapeoftheworkpiece:laserprocessinghasgoodflexibility,canprocessanygraphics,andcancutpipesandotherprofiles.

8. Машината за лазерно рязане може да реже различни материали: пластмаса, дърво, PV кожа, текстил, плексиглас и др.

9.Savemoldinvestment:Laserprocessingdoesnotrequiremolds,nomoldconsumption,nomoldrepairs,andsavingtimeformoldreplacement,therebysavingprocessingcostsandreducingproductioncosts,especiallysuitableforprocessinglargeproducts.

10.Materialsaving:Usingcomputerprogramming,productsofdifferentshapescanbecuttomaximizetheutilizationofmaterials.

11.Improvethespeedofsampledelivery:Aftertheproductdrawingisformed,laserprocessingcanbeperformedimmediately,andthephysicalobjectofthenewproductcanbeobtainedintheshortesttime.

12. Безопасност и опазване на околната среда: Лазерната обработка има по-малко отпадъци, ниско ниво на шум, чисто, безопасно и без замърсяване, което значително подобрява работната среда.

Технически параметри

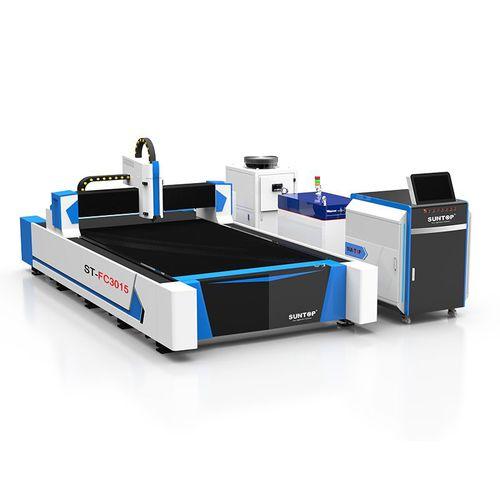

Модел на устройството | |

Лазерен тип | Фибролазер |

Лазерна работна среда | YVO4 |

лазерна дължина на вълната | 1064 nm |

Номинална изходна мощност | 2000W |

Качество на лъча | <0.373mrad |

Ефективен обхват на рязане | 3000×1500 мм |

Точност на аксиално позициониране на работната маса | ≤±0,0 mm/m |

Повторете точността на позициониране на работната маса | ≤±0,0 мм |

Максимална товароносимост на работната маса | 800 кг |

Powerdemand | 380V/50Hz/100A |

Предимство на оптичното влакно

ФибролазерcuttingmachineusesfiberlasertoproduceThelasercuttingmachinewiththelightsourceasthelightsource.

TheadvantagesoffiberlasercuttingmachineoverCO2lasercuttingmachine:

1) Отлично качество на лъча: по-малко фокусирано място, по-фини линии на рязане, по-висока ефективност на работа и по-добро качество на обработка;

2)Extremelyhighcuttingspeed:2timesthatofthesamepowerCO2lasercuttingmachine;

3) Изключително висока стабилност: използване на световно спрян внос на лазер с оптични влакна, стабилна производителност.

4)Veryhighelectro-opticalconversionefficiency,energysavingandenvironmentalprotection;

5)Verylowcostofuse:thepowerconsumptionofthewholemachineislowerthanthatofco2,Savedproductioncosts

6) Много ниски разходи за поддръжка: без работещ с лазер газ; предаване на оптични влакна, без отразяващи лещи; може да спести много разходи за поддръжка;

7)productoperationandmaintenanceareconvenient:Opticalfibertransmission,noneedtoadjustthelightpath;

8) Свръхгъвкав световоден ефект: малък размер, компактна структура, лесни за гъвкави изисквания за обработка.ThefiberlasercuttingmachineadoptstheuniquedesignofGermantechnologyandspecialinnercavitytoensurethestableoperationofthesystemandtheconstantandlastingpower.Thecuttinggapisuniform,anditisconvenienttoadjustthelightandmaintain.Theenclosedlightpathguideslighttoensurethecleanlinessandservicelifeofthelens.

Фибролазерcuttingmachinehashighcuttingprecision,whichissuitableforcuttingprecisionpartsandfinecuttingofvariouscraftcharactersandpaintings.Thecuttingspeedisfast,whichismorethan100timesthatofwirecutting.Theareaofheat-affectedareaissmall,theperformanceisstable,continuousproductionisguaranteed,itisnoteasytobedeformed,thecuttingseamissmoothandbeautiful,andthereisnoneedforsubsequentprocessing.ComparedwiththeCNCpunchingmachine,thefiberlasercuttingmachinecancompletetheprocessingofvariouscomplexstructures.Aslongasanyimagecanbedrawnonthecomputer,themachinecancompletetheprocessing.Thereisnoneedtoopenthemold,justmakethedrawingonthecomputer,andtheproductcanbereleasedimmediately.Itcanquicklydevelopnewproductsandsavecosts.ThecomplexprocessrequirementsaredifficulttoachievewithCNCpunches,andfiberlasercuttingmachinescandoit.

Inaddition,thesurfacecutbythefiberlasercuttingmachineisverysmooth,whichisdifficultforCNCpunchingmachinestoreach.Фибролазерcuttingmachinesarewidelyusedinadvertisingsignproduction,sheetmetalstructure,highandlowvoltageelectricalcabinetproduction,textilemachineryparts,kitchenutensils,automobiles,machinery,elevators,electricalparts,springs,subwaypartsandotherindustries.

Intermsofprice,fiberlasercuttingmachineisslightlymoreexpensivethanordinarylasercuttingmachine,butfromanoverallpointofview,fiberlasercuttingmachineisthemostcost-effective.

Използване и поддръжка

Howtouseandmaintainthefiberlasercuttingmachine?Whenusingafiberlasercuttingmachinetoprocessobjects,itisnecessarytolearntheequipmentuseandmaintenanceskillsofthefiberlasercuttingmachineinordertobetterexerttheefficiencyoftheequipmentandmaximizetheefficiencyoftheequipment.

Как да използвате и поддържате машината за лазерно рязане на влакна:

1)Checkthesteelbeltfrequentlytoensurethatitistight.Otherwise,ifthereisaprobleminoperation,itmayhurtpeople,orevencausedeathinseriouscases.Thesteelbeltlookslikeasmallthing,buttheproblemisstillabitserious.

2)Checkthestraightnessofthetrackandtheverticalityofthemachineeverysixmonths,andifitisfoundtobeabnormal,itwillbemaintainedanddebuggedintime.Ifthisisnotdone,thecuttingeffectmaynotbesogood,theerrorwillincrease,andthecuttingqualitywillbeaffected.Thisisthetoppriorityandmustbedone.

3)Useavacuumcleanertoremovedustanddirtfromthemachineonceaweek.Allelectricalcabinetsshouldbeclosedanddust-proof.

4)Theguiderailsshouldbecleanedfrequentlytoremovedustandotherdebristoensurethattheequipmentisnormal.Therackshouldbewipedfrequentlyandlubricatedtoensurelubricationwithoutdebris.Theguiderailshouldbecleanedandlubricatedfrequently,andthemotorshouldalsobecleanedandlubricatedfrequently.Themachinecanmovebetterandcutmoreaccurately,andthequalityofthecutproductswillbeimproved..

5)Thedual-focuslasercuttingheadisafragileitemonthelasercuttingmachine.Long-termusewillcausedamagetothelasercuttinghead.

Фибролазерcuttingmachineneedsregularinspectionandmaintenance.Ifthereisanydeformationorotherforms,youshouldknowthatthelasercuttingheadisabitdamagedatthistimeandneedstobereplaced.Failuretoreplaceitwillaffectthecuttingqualityandincreasethecost.Someproductsmayhavetoundergosecondaryprocessingandreduceproductionefficiency.ThelasercuttingheadmustbemanufacturedbyHuagongFaril,anditmustbecarefullycheckedwhenthegoodsarereceived,soastoavoidproblemswhentheyareused.

Custombeam

Thecustombeamshapeinthefiberlasercuttingmachineisbasedonaprinciple,thatis:Comparedwiththetraditionallasercuttingusingasinglecircularlaserbeam,thenewcuttingprocessAcomplexlaserbeamshapeisused.Theuniquefocusingcharacteristicsofhigh-powersingle-modefiberlasersareusedtogeneratecomplexbeamshapesandmakeitpossibletoseparateapartoftheoveralllaserenergyinordertocreatea"keyhole"forlaserweldingorlasercuttingapplications.Therestoftheenergywillbedistributedtothemelt;beforethat,themainbeamisusedtocreateanappropriatelyhighvaporpressuredistributiononthesurfaceofthemoltenmaterial.Thismakesitpossibletoapplylocalpressureonthemeltflowingoutoftheincision,whichfarexceedsthepressureofthecoaxialgasjetcommonlyusedinlasercutting.Asaresult,theincisionisverynarrow.Thenewprocesshasgreatpotential.Itwillnotproduceburrsinalargecuttingspeedrange,andcanalsoperformhigh-speedcuttinginnarrowcontourcuttingtoproducehigh-qualitycuts.

Бързо прототипиране

TherapidprototypingtechnologyinthefiberlasercuttingmachineisthegeneraltermfortherapidproductionofsamplesorpartsdirectlybasedontheCADmodel.ItintegratesmodernscientificandtechnologicalachievementssuchasCADtechnology,numericalcontroltechnology,lasertechnologyandmaterialtechnology,andisanimportantpartofadvancedmanufacturingtechnology.Itcanautomatically,directly,quicklyandaccuratelymaterializedesignideasintoprototypeswithcertainfunctionsordirectlymanufacturepartsaccordingtoCADmodels(electronicmodels),andgeneratealmostarbitrarilycomplexpartswithoutusingmoldsandtools.Theproblemofrapiddockingfromdesigntomanufacturing.Therefore,thetechnologycanquicklyevaluateandmodifyproductdesign,effectivelyshortentheproductdevelopmentcycle,reducedevelopmentcosts,andmeettherequirementsoftoday'shighlycompetitivemarketforrapiddevelopmentandrapidmanufacturingofnewproducts,andimproveThemarketcompetitivenessofproductsandthecomprehensivecompetitivenessofenterprises.

Воден охладител

Asasupportingcoolingdeviceforfiberlasercuttingmachine,waterchillerensuresthatthefiberlasercuttingmachineoperatesnormallyataconstanttemperature.Thespecialchillerforfiberlasercuttingmachineisarefrigeratedindustrialchiller.Ithastwoworkingmodes:constanttemperatureandintelligenttemperatureadjustment,andthetemperaturecontrolaccuracyis±0.3℃.Theconfigurationisrich,includingtheinputandoutputcontrolequipmentswitchandtheadvancedfunctionsofcoolingwaterflow,highandlowtemperaturealarm,stableanddurableperformance,andparticularlyexcellentinenergysavingandenvironmentalprotection.

Технически параметри:

One-stopautomaticintelligenttemperaturecontrol:Indifferentenvironments,userscanautomaticallyswitchtotheappropriatecontroltemperaturewithoutchanging;

CW-6100AT: Може да се използва за охлаждане на един 300W-1000W фибролазер.

Оборудван с нагревател и конфигурация за пречистена вода.

Модел | CW-6100AT | CW-6100BT |

Работно напрежение | AC1P220V | AC1P220V |

Работна честота | 50Hz | 60Hz |

Работен ток p> | 1~6.5A | |

Мощност на компресора | 1.38KW | 1.29KW |

1.84HP | 1.72HP | |

Хладилен капацитет | 930Btu/h+13640Btu/h | 930Btu/h+12958Btu/h |

0.3KW+4KW | 0.3KW+3.8KW | |

180Kcal/h+3440Kcal/h | 180Kcal/h+3268Kcal/h | |

хладилен агент | R-22/R-410a | |

Сума на таксата | 950гр | 900гр |

Точност на контрол на температурата | ±0,5 ℃ | |

Дросел | Капилярна | |

Защита на безопасността | Защита от свръхток на компресора, аларма за поток, аларма за превишена температура | |

Водна помпа | 0.1KW+0.55KW | |

Капацитет на резервоара за вода | 4L+12L | |

Вход и изход | Rp1/2"+Rp1/2" | |

Максимална глава | 25M+28M | |

Максимален дебит | 16L/min+58L/min | |

Нето тегло | 65 кг | |

Брутно тегло | 75 кг | |

Размер на машината | 60X47X89 см (дължина X ширина X височина) | |

Размер на пакета | 74X60X109 см (дължина X ширина X височина) |

Предпазни мерки при употреба:

1,Pleasemakesurethatthepowersocketisingoodcontactandthegroundwireisreliablygrounded!

2,pleaseensurethattheworkingvoltageofthechillerisstableandnormal!

Becausetherefrigerationcompressorismoresensitivetothepowersupplyvoltage,thenormalworkingvoltageofourcompany'sstandardproductsis200~250V(110Vmodelis100~130V).Ifyoureallyneedawideroperatingvoltagerange,youcancustomizeitseparately.

3.Mismatchedpowerfrequencywillcausedamagetothemachine!

Pleaseusethe50Hzor60Hzmodelaccordingtotheactualsituation.

4.Toprotectthecirculatingwaterpump,itisstrictlyforbiddentorunwithoutwater!

Thewaterstoragetankhasbeenemptiedbeforethenewmachineispacked.Pleasemakesurethatthewatertankisfilledwithwaterbeforeturningiton,otherwisethewaterpumpiseasilydamaged.Whenthewaterlevelofthewatertankisbelowthegreen(NORMAL)rangeofthewaterlevelgauge,thecoolingcapacityofthechillerwillslightlydecrease.Pleaseensurethatthewaterlevelofthewatertankiswithinthegreen(NORMAL)rangeofthewaterlevelgauge.Itisstrictlyforbiddentousethecirculatingpumptodrainwater!

5.Pleaseensurethattheairinletandoutletchannelsofthechilleraresmooth!

Theairoutletonthechillermustbeatleast1250pxawayfromtheobstacle,andtheairinletonthesidemustbeatleast500pxawayfromtheobstacle.

6. Филтърът на въздушния отвор трябва да се почиства редовно!

Thedustscreenmustberemovedandcleanedregularly.Seriousblockageofthedustscreenwillcausethechillertomalfunction.

7.Pleasepayattentiontotheinfluenceofcondensationwater!

Whenthewatertemperatureislowerthantheambienttemperatureandtheambienthumidityishigh,condensedwaterwillbegeneratedonthesurfaceofthecirculatingwaterpipeandthecooleddevice.Whentheabovesituationoccurs,itisrecommendedtoincreasethewatertemperatureorheatthewaterpipeandthecooleddevice.

8. Този продукт е промишлено оборудване, моля, не го експлоатирайте от непрофесионалисти.

Въздействие

Withtherapidexpansionofsheetmetalprocessingtechnology,domesticprocessingtechnologyisalsomovingatarapidpace,andthegapwithforeigncountriesisgettingsmallerandsmaller.Manywell-knownforeigncompanieshaveThemanufacturingbasewastransferredtoChina,andthefiberlasercuttingmachinealsobroughtmanyreactionaryconceptstosheetmetalprocessing.

Lasercuttingmachineisatechnologicalrevolutioninsheetmetalprocessing,anditisthe"processingcenter"insheetmetalprocessing;lasercuttingmachinehasahighlevelofflexibility,fastcuttingspeed,highconsumptionefficiency,andshortproductconsumptioncycle,Towinthegeneralmarketforcustomers.Thelasercuttingmachinehasnocuttingforceandnodeformationinprocessing;notoolwearandgooddatacompliance;nomattersimpleorcomplexparts,itcanbecutwithlaserprecisionandrapidformingatonetime;itscuttinggapisnarrow,cuttingqualityisgood,andthelevelofautomationishigh.Theoperationissimple,thelaborintensityislow,andthereisnopollution;itcancompletecuttingandautomaticnestingandnesting,whichimprovesthedataapplicationrate,lowconsumptioncost,andgoodeconomicefficiency.Thetechnologyhasalongeffectivelifespan.Atpresent,fiberlasercuttingmachinesaremostlyadoptedforsheetswithathicknessofmorethan2MMinforeigncountries.Manyforeignexpertsanalyzethatthenext30-40yearswillbethegoldenperiodoflaserprocessingtechnologyexpansion(thedirectionofsheetmetalprocessingexpansion)).