Introduction

Development board is aimed at a certain chip, with this chip as the core, expand the function of this chip, and demonstrate each part of the function through the program . At the same time, the source program and schematic diagram are provided, so that customers can learn the use of this chip at the least cost and the fastest speed, achieving a multiplier effect with half the effort.

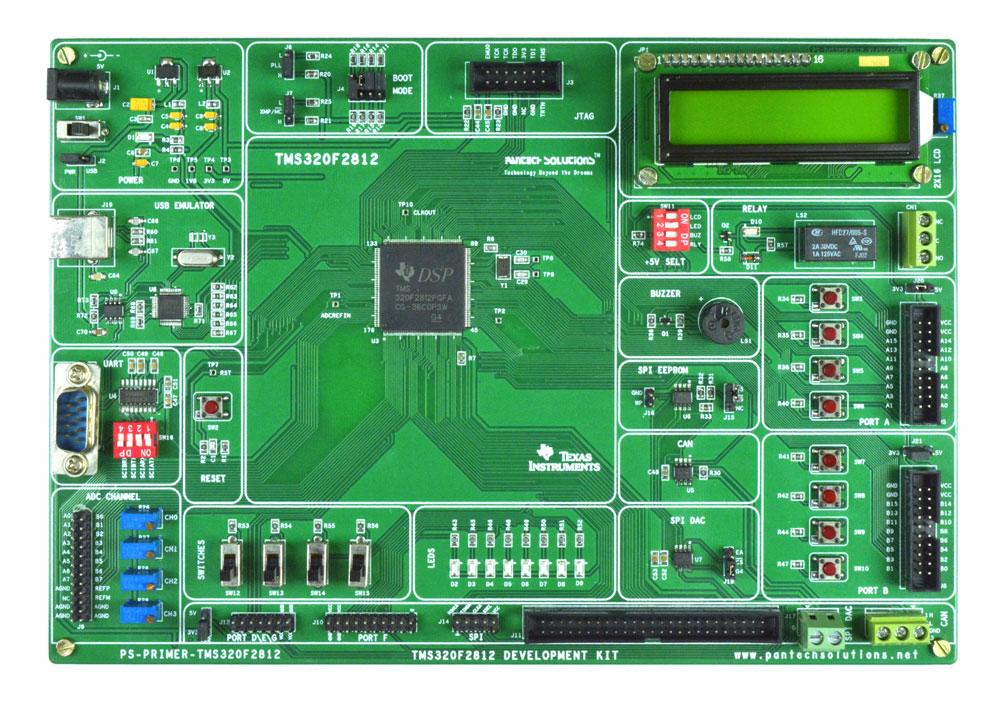

Module function

DSP development board is to research and develop the function of DSP, launch the circuit board for DSP chip development, and provide the schematic diagram and source code to customers. DSP, in particular, has the largest market share in the DSP market of TI, and has a very wide customer base. In terms of DSP development boards, the Easy series DSP development boards include Easy2812 development boards and Easy5509 development boards, which are especially suitable for students to learn and use. It also launched QQ series development boards, including QQ2812 development boards, QQ5509 development boards, etc., suitable for company R&D personnel.

The driver-assisted system technology urgently needed by consumers requires high-reliability components with advanced precision functions and very small dimensions. Because these systems are small in size and very close to each other, they also require devices with ultra-low power consumption and good durability. The thermal reliability problems in the design of space-constrained systems can be solved by using fewer components and ultra-low power consumption.

In the past, automotive engineers usually relied on MCU (microcontroller) and custom ASIC (application specific integrated circuit) products to control the electronic system on the car and realize the functional expansion of new models. But with the increasing number of components, shorter development cycle requirements, and higher performance requirements, engineers have to find new alternative technologies, such as low-cost, low-power and high-reliability FPGAs. In the field of automotive electronics, where the market capacity continues to grow, space and power-constrained safety devices, passenger sitting posture detection systems (PODS), rear-view and side-view cameras, and telematics solutions can all benefit from Actel’s low-power FPGAs.

Compared with MCU, FPGA can enable automotive system design to achieve better performance and more functions (such as I/O, programmable logic, etc.). Similarly, compared with ASIC products, FPGAs are cheaper and more flexible. Unlike ASIC, FPGA can also be applied to a variety of projects once there is a complete qualification program, which helps designers gain time and give full play to the potential of resources to deal with various qualifications in the automotive industry.