Introduction

produces X-rays vacuum electronics using high-speed electron impact metal target surfaces. The X-ray tube can be divided into a pneumatic tube and a vacuum tube.

Inflatable X-ray tube is an early X-ray tube. In 1895, W.C. Lonen piano found X-rays when carrying the Croks tube experiment. The Cruks tube is the earliest inflatable X-ray tube. After this tube is turned on, the gas is ionized in the tube, under the homogenesis, the electrons are escorted from the cathode, and the Targeting the target surface generates X-rays after acceleration. Inflatable X-ray tube is small, short life, difficult to control, and have little application. In 1913, W.D. Kurgi invented the vacuum X-ray tube. The true vacuum in the tube is not less than 10-4 Pa. The cathode is a metal target for a hot-heat spiral tungsten wire, an male pole is a metal target. The target and electron beam energy are selected depending on the use of the tube, and the tungsten target is often used. Under certain purposes, silver, palladium, rhodium, molybdenum, copper, nickel, cobalt, iron, and chromium are also used. The cathode operating temperature is approximately 2000K, and the emitted electronics tens of thousands to hundreds of thousands of volts high pressure accelerated after the target surface. The cathode is surrounded by a metal cover slotted in a front end. The potential of the metal cover is equal to or lower than the cathode, forcing electronically focused a narrow region on the target surface to form a focal spot. The X-ray radiates from the focal spot to the respective directions, and outputs the window on the tube wall. The window is generally made of a small beryllium, aluminum or light glass absorbed by X-rays, and is the best with the tab.

principle

X-ray tube includes two electrodes of the anode and cathode, which are used to receive electron bombardment targets and filaments that emit electrons. The two poles are sealed in a high vacuum glass or ceramic housing. The X-ray tube power supply portion includes at least one high voltage generator that allows the filament heating and a high voltage to which a high voltage is applied to the two poles. When the tungsten wire produces an electronic cloud by sufficient current, there is a sufficient voltage (kV grade) to be added between the anode and the cathode, so that the electronic cloud is pulled to the anode. At this time, the electrons hit the tungsten target in a high-speed state, high-speed electron to reach the target surface, and the movement suddenly blocked, and a small portion of the kinetic energy is converted into radiation energy, released in the form of X-rays, in this form of radiation It is radiated. Changing the size of the filament current can change the temperature of the filament and the emission amount of the electrons, thereby changing the size of the tube current and the X-ray intensity. Changing the X-ray tube excitation potential or selecting different targets can alter the energy of the incident X-rays or the strength at different energy. Due to high-energy electron bombardment, the temperature of the X-ray tube is high, and the anode target is required to be forced cooling. Although the energy efficiency of X-rays produces X-rays is very low, the X-ray tube is still the most practical X-ray generating device, which has been widely used in X-ray instruments. At present, medical applications are mainly divided into X-ray tubes and treasury with X-ray tubes.

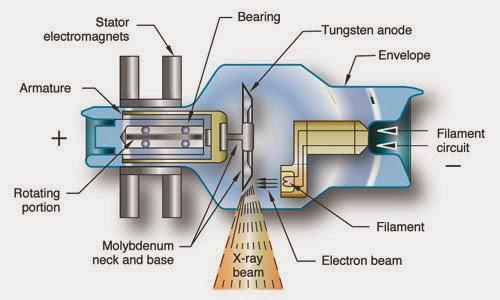

The requirements for the X-ray tube are small focus, large intensity to form a large power density. Therefore, in the anode, it is necessary to supply a relatively large power, but the efficiency of the X-ray tube is very low, and 99% or more electron beam power becomes an anode hot consumption, and the focus is overheating. The method of avoiding an anode overheating is to take cooling of the anode or tube to reduce the temperature at the focal spot, or incline the target surface to provide a larger heat dissipation area. After the rotary anode X-ray tube, the high speed rotation of the target surface (up to 10,000 rpm), the power density is high, the focus is small. Modern has an X-ray tube equipped with a control gate between the anode target surface and the cathode, and a pulse modulation is applied on the control gate to control the output of the X-rays. Change the pulse width and repetition frequency, adjust the timing repeated exposure.

Classification

The X-ray tube can be divided into a pump and a vacuum tube according to the generation of electronics.

can be divided into glass tubes, ceramic tubes, and metal ceramic tubes depending on the material of the sealing material.

can be divided into medical X-ray tube and industrial X-ray tube depending on the purpose.

can be divided into an open X-ray tube and a closed X-ray tube depending on the sealing method. Open X-ray tube needs to be empty during use. The closed X-ray tube produces X-ray tubes to take advantage of the vacuum to a certain degree, immediately sealed, no need to make it again during use.

Structure

Fixed anode X-ray tube is the simplest in common X-ray tube, its structure consists of an anode, a cathode and a fixed pole, and maintains a high vacuum glass shell in a glass tube. Waiting for three parts.

The anode is composed of an anode head, an anode cap, a glass ring and an anode handle. The main role of the anode causes X-rays from the target surface of the anode (generally selected tungsten target) to generate X-rays, and the heat radiation thus generated or conducted by an anode handle, and absorbs secondary electrons and disabled Rays. The X-ray in the tungsten alloy X-ray tube is only used by 1% of the high-speed motion electron flow, so heat dissipation is an important issue for X-ray tubes. The cathode is mainly composed of a filament, a focus cover (or a cathode head), a cathode sleeve, and a glass core column. The electron beam of the root anode target is emitted by the filament of the heating cathode (generally tungsten wire), and is focused by the high voltage acceleration of the tungsten alloy X-ray tube. High-speed electron beam hits the anode target and suddenly blocked, a certain energy consecutive distribution X-ray (which is also reflects the feature of the anode target metal).

Application

X-ray tube in medicine for diagnosis and treatment, in industrial technology for material loss Detection, structural analysis, spectral analysis and negative film exposure. X-rays are harmful to the human body, and effective protective measures must be taken during use.

Common fault analysis

fault 1 : Rotate the anode rotor Failure

(1) phenomenon

1 circuit is normal, but the speed is significantly decreased; the static time is short; the anode does not rotate during exposure; 2 When exposed, the tube current is increased, the power fuse is blown; the anode target surface is melted.

(2) Analysis

After long-term operation, the bearing wear deformation and gap changes, the solid lubricant molecular structure also changes.

Fault 2 : x ray tube anode target surface damage

(1) phenomenon < / p>

1 X-ray output significantly decreased, X-ray film sensitivity is insufficient; 2 Since the anode metal is evaporated, the glass wall plating has a thin metal layer; 3 through the magnifying glass, visible target surface has cracks , Cracks and molten and other phenomena; 4 Metal tungsten splashing when the focus is severely melted, may cause the X-ray tube to burst damage.

(2) Analysis

1 overload use. There are two possibilities: One is the failure of overload protection circuit makes an exposure; the other is multiple exposure, causing cumulative overload to melt evaporation; 2 Rotate anode X-ray tube rotor die or activate the protection circuit fault, When the anode does not rotate or the speed is too low, it is exposed to cause an anode target surface to be melted; 3 heat dissipation. If the heat sink and the anode copper have no tight or too much oil.

fault three : x ray tube filament opening

(1) phenomenon

1 When exposed, there is no X-ray generation, and the milliacies have no indication; 2 can be seen by the X-ray tube window; 3 Measure the X-ray tube filament, the resistance is infinite.

(2) Analysis

1 X-ray tube filament voltage is too high, burn the filament; 2 X-ray tube vacuum is destroyed, a large amount of intake is rapidly oxidizing the filament Burn.

Fourth : Photograph No x line generated failure

(1) phenomenon < / p>

1 photography also does not have X-ray generation.

(2) Analysis

1 If the photography does not produce the X-ray, it is generally to determine whether the high pressure can be sent to the ball tube, directly in the actuch

Measuring the voltage. Take Beijing Wandong as an example, general high-voltage transformer initial secondary voltage ratio is 3: 1000, of course, pay attention to the space under the machine. This space is mainly due to the internal resistance of the power supply, the autoiler transformer, and the like, and the loss is increased, resulting in a decrease in input voltage, etc., the loss is related to mA, the larger, the larger the loss, the larger loss, The higher the load detection voltage should also be. Therefore, when the voltage measured by the maintenance person exceeds 3: 1000, it is normal, and the exceeding value is related to the mA, the larger, the greater this value. This can be judged whether or not there is a problem with the high pressure primary circuit.