Overview

On the semiconductor substrate, there are: a plurality of pads arranged at the edge of the circuit block and a plurality of pads extending from the circuit block to between the pads Multiple wiring; the multiple pads are connected to the external leads of the semiconductor integrated circuit device, and the multiple wirings are used to follow from when another circuit block is provided on the main surface of the semiconductor substrate The wiring connected to the wiring of the other circuit block is formed to have a shape that can be connected to the wiring from the other circuit block.

Semiconductor integrated circuits are the core devices of electronic products, and the development of its industrial technology is directly related to the development level of the power industry. In terms of the overall situation, the technological progress of the semiconductor industry has promoted the development of emerging industries to a certain extent, including photovoltaic industry, semiconductor lighting industry and flat panel display industry, etc., and has promoted the improvement of the supply chain of the upstream and downstream industries of the semiconductor integrated circuit industry. , And optimize the ecological environment to a certain extent. Therefore, strengthening the research and exploration of the semiconductor integrated circuit industry technology has important practical significance.

Quality assurance measures

Process assurance

1) Raw material control. Including the control of masks, chemical reagents, photoresist, especially silicon materials and other raw materials. Control not only uses the traditional single inspection method, but also uses statistical process control (SPC) technology for key raw materials to ensure high quality of raw materials and good quality consistency.

2) Control of processing equipment. In addition to the use of advanced equipment for process processing, routine maintenance and preventive maintenance of equipment should also be carried out. At the same time, key parameters of the equipment should be monitored, and SPC control models of equipment parameters should be established for analysis and control if necessary.

3) Process control. Including SPC control of key process parameters, process capability analysis, 6σ design, etc., while establishing process inspection methods for key aspects of process processing, such as the inspection of pinholes and cracks in the oxide layer, the inspection of movable metal ions, and the inspection of metal Layer stability inspection, etc. In addition, the process guarantee should also include the training and assessment of operators, the control of environmental cleanliness, and the establishment of advanced production quality management information systems.

Design guarantee

1) Conventional reliability design technology. Including redundant design, derating design, sensitivity analysis, central value optimization design, etc.

2) Device design technology for major failure modes. Including the rational design of device structure, geometric parameters and physical parameters for the main failure modes such as hot carrier effect and latch-up effect.

3) Process design guarantee for main failure modes. Including the adoption of new process technology and adjustment of process parameters to improve the reliability of semiconductor integrated circuit chips.

4) Computer simulation technology of semiconductor integrated circuit chip reliability. At the same time of circuit design, the circuit structure, layout layout and reliability characteristic parameters are used as input, and the reliability of the circuit is analyzed by computer simulation. According to the analysis results, the reliability level of the circuit can be predicted, the design rules that should be adopted in the reliability design are determined, and the weak links in the reliability of the circuit and layout design are found.

Manufacturing process

The integrated circuit has integrated the core part of a microcomputer on a silicon chip about 5mm×5mm in size, containing more than 10,000 components. The typical manufacturing process of integrated circuits is shown in Figure 1. From Figure 1, it can be seen that an N+PN transistor, a resistor composed of a P-type diffusion region and a capacitor composed of an N+P junction capacitance have been fabricated on the silicon wafer at the same time, and they are connected by a metal aluminum strip. Connected together. In fact, on a commonly used silicon wafer with a diameter of 75mm (which has been developed to φ=125mm~150mm), there will be 3,000,000 such components, which constitute hundreds of circuits, subsystems or systems. Through a series of processes such as oxidation, photolithography, diffusion or ion implantation, chemical vapor deposition evaporation or sputtering, all the components of the entire circuit, their isolation and metal interconnection patterns are manufactured on a single wafer layer by layer. Above, forming a three-dimensional network. However, dozens or even hundreds of such silicon wafers can be processed at the same time at a time, so thousands of such circuits can be obtained in one batch. Such high efficiency is precisely the technical and economic reason for the rapid development of integrated circuits.

This three-dimensional network can have a variety of different circuit functions and system functions, depending on the topological graphics and process specifications of each layer. Under certain technological specifications, it is mainly controlled by the topological pattern of each layer, and the topological pattern of each layer is determined by each photoetching mask. Therefore, the design of the photolithography mask is a key to the manufacture of integrated circuits. It starts from the functional requirements of the system or circuit, designs according to the actual possible process parameters, and is assisted by the computer to complete the design and mask manufacturing.

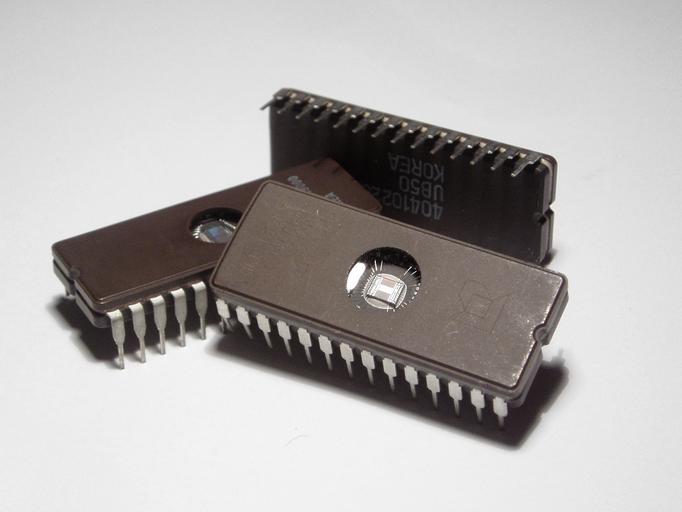

After the chip is manufactured, it is inspected, and then the chips on the silicon chip are cut off one by one, and the chips that meet the performance requirements are packaged on the shell to form a complete integrated circuit.

Classification

If integrated circuits are distinguished by the transistors that form the basis of their circuits, there are two types of bipolar integrated circuits and MOS integrated circuits. The former is based on bipolar junction planar transistors (Figure 2), and the latter is based on MOS field effect transistors. Figure 3 shows the manufacturing process of a typical silicon gate N-channel MOS integrated circuit. Generally speaking, the advantages of bipolar integrated circuits are faster speed, but the disadvantages are lower integration and higher power consumption; while MOS integrated circuits have simpler process, higher integration, and higher power consumption due to the self-isolation of MOS devices. Lower, the disadvantage is that the speed is slower. Various new devices and circuit structures have emerged recently in the development of taking advantage of their respective advantages and overcoming their own shortcomings.

Integrated circuits are classified according to circuit functions. There can be mathematical logic circuits based on gate circuits and linear circuits based on amplifiers. The latter is slower than the former due to the harmful interaction between the semiconductor substrate and the working components. At the same time, microwave integrated circuits used in microwaves and optical integrated circuits based on III-V compound semiconductor lasers and optical fiber conduits are also under development.

In addition to silicon-based materials for semiconductor integrated circuits, gallium arsenide is also an important material. Integrated circuits made with it as a basic material can operate at an order of magnitude higher than that of silicon integrated circuits. Broad prospects for development.

From the perspective of the entire integrated circuit category, in addition to semiconductor integrated circuits, there are thick film circuits and thin film circuits.

①Thick film circuit. Using ceramics as a substrate, passive components and interconnecting wires are prepared by process methods such as screen printing and sintering, and then mixed and assembled with components such as transistors, diodes, integrated circuit chips, and discrete capacitors.

②Thin film circuit. There are full film and mixed points. The so-called full-film circuit refers to all the active components, passive components and interconnection conductors required to form a complete circuit, all of which are made on an insulating substrate by a thin-film process. However, film transistors have poor performance and short lifespan, making them difficult to practically use. Therefore, the thin-film circuit mainly refers to the thin-film hybrid circuit. It uses vacuum evaporation and sputtering and other thin film technology and photolithography technology to use metals, alloys and oxides to manufacture resistors, capacitors and interconnections on glass-ceramic or ceramic substrates (the thickness of the film generally does not exceed 1 micron), and then It is assembled with one or more transistor devices and integrated circuit chips at high density.

Compared with monolithic integrated circuits, thick film and thin film circuits have their own characteristics and complement each other. Thick-film circuits are mainly used in high-power fields; while thin-film circuits are mainly used in high-frequency and high-precision applications. The mutual penetration and combination of monolithic integrated circuit technology and hybrid integrated circuit technology, and the development of ultra-large-scale and full-function integrated circuit systems, has become an important direction for integrated circuit development.

Development trend

As far as the actual development of IC industry technology is concerned, the reduction in IC integration growth rate will not lead to the stagnation of the microelectronics industry. The IC industry can Realize modern development in terms of product diversity and product performance. With the continuous development of the IC industry, IC products can better meet the actual needs of the market. IC industry designers can design and manufacture IC products based on the actual needs of industry customers, and then launch diverse IC products and ensure their functions Get a certain degree of optimization. At the same time; during the development of the IC industry, efforts can be made to reduce the manufacturing costs of existing process equipment, so as to promote the balanced and stable development of the IC industry. From another perspective, the slowdown in the growth rate of IC integration has prompted computer system and software developers to have more time and energy to study IC products and improve IC product performance.

Currently, the scale of the IC industry in mainland China is relatively small, accounting for only a small part of the global IC industry. In general, China’s IC industry is relatively lagging behind the international market in terms of economy and technology. Advanced level. In recent years, the State Council has issued relevant documents on the development of the IC industry, which has stimulated domestic IC industry investment to a certain extent, thereby promoting the increase in the growth rate of China's IC industry.