Inverterweldingmachine

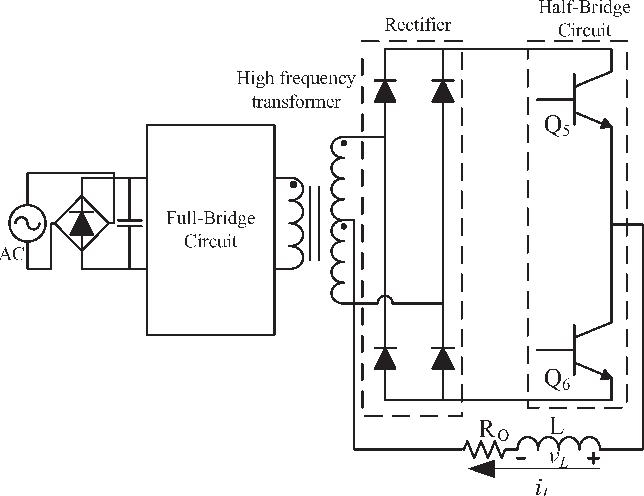

Theworkingprocessofinverterweldingmachinerectifiesthree-phaseorsingle-phasepowerfrequencyalternatingcurrent,andobtainsasmootherdirectcurrentafterfiltering,whichiscomposedofIGBTs.ThevariablecircuitconvertsthedirectcurrentintotensofKHZalternatingcurrent.Afterthemaintransformerissteppeddown,itisrectifiedandfilteredtoobtainasmoothDCoutputweldingcurrent.

Becausetheinverterworkingfrequencyisveryhigh,thecorecross-sectionalareaofthemaintransformerandthenumberofturnsofthecoilaregreatlyreduced.Therefore,theinverterweldingmachinecanthrottlethemetalmaterialandreducetheoverallsizeataveryhighlevel.Andweight,greatlyreducingthepowerloss,andmoreimportantly,theinverterweldingmachineweighingandmeasuringlengthcanadjusttheoutputcurrentinmicroseconds,sothatitcanbecometheidealcontrolrequiredbytheweldingprocess.Throughtheprocess,asatisfactoryweldingeffectwasobtained.

Althoughthecircuitisclosed,itispreciselybecausethecircuitisclosedthatthecircuitandthecurrentmustbeequaleverywhere;buttheresistanceacrossthegroundisdifferent,especiallyintheplacewherethecontactisnotfixed.Theresistanceisthelargest.Thisresistanceiscalledthemiddleresistanceinphysics.Accordingtothelawofthermaleffectofcurrent(alsocalledJoule'slaw),Q=IsquareRtshowsthatthecurrentisequal,thegreatertheresistance,thehigherthefever,andthecontactoftheelectrodeisalsocontactedbythemetalbodyduringwelding.Theconnectionresistanceattheplaceisthelargest,sotheelectricheatgeneratedinthispartisnaturallythemost.Theweldingrodisanalloywithalowermeltingpoint,anditisnaturallyeasytomelt.Themoltenalloyelectrodecoreisadheredtotheobjecttobeweldedandthencooled.,Theweldingobjectisgluedtogether.

Becausetheinverterweldingmachineisatypicalswitchingpowersupply(theoutputcharacteristicshavegreatcharacteristics),theoutputpowerislarge,andtheworkingconditionschangegreatly,sothequalityofthecomponentsisrequiredtobegood,andtheworkcanbesupervisedinthisway.Thestabletype,longlife.

Advantagesoftheinverterweldingmachine

Becausetheinverterworkingfrequencyisveryhigh,thecorecross-sectionalareaofthemaintransformerandthenumberofcoilturnsaregreatlyreduced.Therefore,theinverterweldingmachinecanbeusedinItsavesmetalmaterialstoalargeextent,reducesthesizeandweight,andgreatlyreducesthepowerloss.Moreimportantly,theinverterweldingmachinecanadjusttheoutputcurrentinasubtletime,soitcanachievetherequirementsoftheweldingprocess.Ideallycontroltheprocessandobtainsatisfactoryweldingresults.

StructuralcharacteristicsofinverterweldingmachineTheweldingheadconvertstheenergyoutputbytheweldingenergyequipmentintoweldingheat,andcontinuouslyfeedstheweldingmaterial,whiletheheaditselfmovesforwardtoachievewelding.

1.Theweldingtongsusedformanualarcwelding,astheweldingrodmelts,theweldingrodmustbemanuallyfeddownwardandmovedforwardtoformaweld.

2.Theautomaticweldingmachinehasanautomaticwirefeedingmechanismandaheadwalkingmechanismtomovetheheadforward.Therearetwocommonlyusedheads,trolleytypeandsuspensiontype.

3.Theweldingheadofresistancespotweldingandprojectionweldingistheelectrodeanditspressuremechanism,whichareusedtoapplypressureandenergizetheworkpiece.

4.Thereisanothertransmissionmechanismforseamweldingtodrivetheworkpiecetomove.Staticanddynamicfixturesandfixtureclampingmechanisms,aswellasmobilefixturesandupsettingmechanismsarerequiredforbuttwelding.

High-frequencyinverterrectifierweldingmachinepowersupply

Duetothepoorworkingconditionsoftheweldingmachinepowersupply,itisfrequentlyinshort-circuit,arcing,andopen-circuitalternatechanges,sohigh-frequencyreverseThereliabilityofthepowersupplyofthevariablerectifierweldingmachinehasbecomethemostcriticalissue,anditisalsotheissuethatusersaremostconcernedabout.Usingamicroprocessorastherelevantcontrollerofpulsewidthmodulation(PWM),throughtheextractionandanalysisofmulti-parametersandmulti-information,thepurposeofpredictingthevariousworkingconditionsofthesystemisachieved,andthesystemcanbeadjustedandprocessedinadvancetosolvetheproblem.Improvethereliabilityofhigh-powerIGBTinverterpowersupply.

Foreigninverterweldingmachinescanachievearatedweldingcurrentof300A,aloaddurationof60%,afullloadvoltageof60~75V,acurrentadjustmentrangeof5~300A,andaweightof29kg.