GasolineInjectionSystem

Classification

Therearemanytypesofgasolineinjectionsystemsforvehicles,whichcanbeclassifiedaccordingtodifferentmethods:

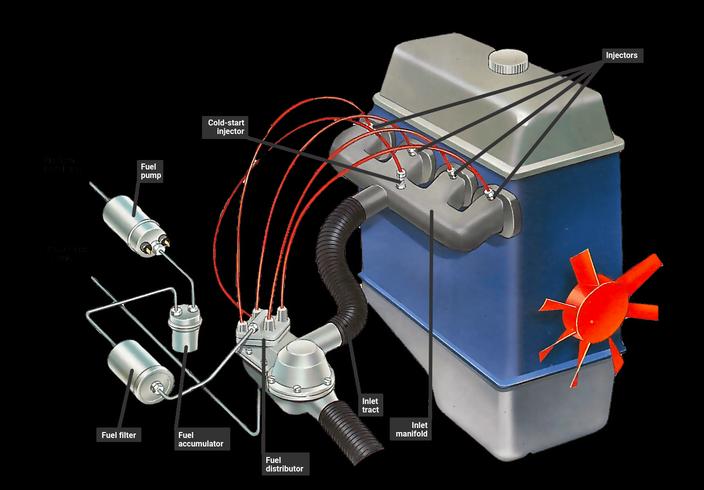

1Accordingtothedifferentinjectionparts,itcanbedividedintotwotypes:in-cylinderinjectionandout-cylinderinjection.In-cylinderinjectionistoinjectgasolinedirectlyintothecylinderthroughaninjectorinstalledonthecylinderhead.Thisinjectionsystemrequiresahigherinjectionpressure,3-5MPapermonth.Therefore,thestructureandlayoutofthefuelinjectoraremorecomplicated.Theout-cylinderinjectionsysteminstallstheinjectorontheintakepipeorintakemanifold,andinjectsgasolineintotheintakepipeorintakeportataninjectionpressureof0.20-0.35MPa.Theformeriscalledintakepipeinjection(single-pointEFI),andthelatteriscalledportinjection(multi-pointinjection).Atpresent,portinjectioniswidelyusedingasolineelectroniccontrolsystems.

2.Accordingtothecontinuityofinjection,thegasolineinjectionsystemisdividedintocontinuousinjectionandintermittentinjection.Continuousinjectionmeansthatduringengineoperation,theinjectorcontinuouslyinjectsintotheintakeport,andmostofthegasolineisinjectedwhentheintakevalveisclosed.Thistypeofinjectionismostlyusedinmechanicallycontrolledorelectromechanicalhybridcontrolledgasolineinjectionsystems.Intermittentinjectionmeansthatgasolineisintermittentlyinjectedintotheintakeportduringengineoperation.Electronicallycontrolledgasolineinjectionsystemsalladoptintermittentinjectionmethods.

Controlprinciple

Whentheenginerunsunderdifferentworkingconditions,therequirementsforthemixtureconcentrationarealsodifferent.Especiallyinsomespecialworkingconditions(suchasstarting,rapidacceleration,rapiddeceleration,etc.),therearespecialrequirementsfortheconcentrationofthemixture.TheECUshouldcontrolthefuelinjectionvolumeindifferentwaysaccordingtotheoperatingconditionsmeasuredbytherelevantsensors.Thecontrolmodeoffuelinjectioncanbedividedintostartcontrol,operationcontrol,fuelcutcontrolandfeedbackcontrol.

1.Startfuelinjectioncontrol

Whenstarting,theengineisdrivenbythestartermotor.Becausethespeedisverylow,thefluctuationofthespeedisalsogreat,sotheintakeairvolumesignalmeasuredbytheairflowsensorhasabigerroratthistime.Forthisreason,whentheengineisstarted,theECUdoesnotusethesignaloftheairflowsensorasthebasisforcalculatingthefuelinjectionvolume,butperformsfuelinjectioncontrolaccordingtoapredeterminedstartingprogram.ECUjudgeswhethertheengineisinthestartingstateaccordingtothesignalofthestartswitchandthespeedsensor,soastodecidewhethertocontrolthefuelinjectionaccordingtothestartprocedure.Whenthestartswitchisturnedonandtheenginespeedislowerthan300rpm,theECUdeterminesthattheengineisinthestartingstate,andcontrolsthefuelinjectionaccordingtothestartprocedure.

Inthestartingfuelinjectioncontrolprogram,theECUcalculatesafixedfuelinjectionvolumeaccordingtotheenginewatertemperature,intakeairtemperature,andstartingspeed.Thisamountoffuelinjectionenablestheenginetoobtaintherichmixturerequiredforasmoothstart.Whenacoldcarstarts,theenginetemperatureisverylow,andthefuelinjectedintotheintakeductisnoteasytoevaporate.Inordertogenerateenoughfuelvaporandformasufficientconcentrationofcombustiblemixturetoensurethattheenginecanstartnormallyatlowtemperatures,thefuelinjectionvolumemustbefurtherincreased.ControlledbytheECU,thefuelinjectionvolumeisincreasedbyincreasingthefuelinjectiondurationorthenumberoffuelinjectionsofthefuelinjectorsofeachcylinder.TheincreasedfuelinjectionvolumeandtheenrichmentdurationarecompletelydeterminedbytheECUbasedonthetemperaturemeasuredbytheintakeairtemperaturesensorandtheenginewatertemperaturesensor.Thelowertheenginewatertemperatureorintakeairtemperature,thegreaterthefuelinjectionvolumeandthelongertheenrichmentduration.Thiscoldstartcontrolmethoddoesnothaveacoldstartinjectorandacoldstarttemperatureswitch.

2.Operationcontrol

Duringengineoperation,theECUmainlycalculatesthefuelinjectionamountbasedontheintakeairvolumeandenginespeed.Inaddition,theECUmustrefertooperatingparameterssuchasthrottleopening,enginewatertemperature,intaketemperature,altitude,idlingconditions,accelerationconditions,andfullloadconditionstocorrectthefuelinjectionvolumetoimprovecontrolaccuracy.

SincetherearemanyoperatingparameterstobeconsideredbytheECU,inordertosimplifythecalculationprocedureoftheECU,thefuelinjectionquantityisusuallydividedintothreeparts:thebasicfuelinjectionquantity,thecorrectionquantity,andtheincrement,andtheresultsarecalculatedseparately.Thenthethreepartsaresuperimposedtogethertocontrolthefuelinjectionoftheinjectorasthetotalfuelinjectionvolume.

Basicfuelinjectionvolume:Thebasicfuelinjectionvolumeisthefuelinjectionvolumecalculatedaccordingtotheintakevolumeofeachengineworkingcycleandthetheoreticalmixingratio(air-fuelratio14.7).

Correctionamount:Correctionamountisbasedonactualoperatingconditionssuchasintakeairtemperature,atmosphericpressure,etc.,toproperlycorrectthebasicfuelinjectionvolume,sothattheenginecanobtainthebestconcentrationofmixedgasunderdifferentoperatingconditions.Thecontentofthecorrectionamountis:intakeairtemperaturecorrection,atmosphericpressurecorrectionandbatteryvoltagecorrection(whenthevoltagechanges,thefuelinjectionpulsewidthisautomaticallycorrected).

3.Feedbackcontrol

Thesensorforfeedbackcontrolofthegasolineinjectionsystemisthehotoxygensensor,andtheengineusingthehotoxygensensormustuseunleadedgasoline.Feedbackcontrol(closedloopcontrol)istoinstallahotoxygensensorontheexhaustpipe.Accordingtothechangeoftheoxygencontentintheexhaust,theair-fuelratiovalueofthemixedgasenteringtheenginecombustionchamberismeasured,anditisinputintotheECUandthesettargetairThefuel-fuelratioiscompared,andtheerrorsignaliscontrolledbytheamplifiertocontroltheamountoffuelinjectedbytheelectromagneticinjector,sothattheair-fuelratioismaintainednearthesettargetvalue.Therefore,closed-loopcontrolcanachievehighair-fuelratiocontrolaccuracy,andcaneliminateperformancechangescausedbyproductdifferencesandwear,etc.,withgoodworkingstabilityandstronganti-interferenceability.However,inordertomakethethree-waycatalyticdeviceachievethebesteffectonexhaustpurificationtreatment,theclosed-loopcontrolledgasolineinjectionsystemcanonlyoperateinaverynarrowrangenearthetheoreticalair-fuelratioof14.7.Therefore,forspecialoperatingconditions,suchasstart-up,warm-up,idlespeed,acceleration,fullload,etc.,wherethemixtureneedstobeenriched,open-loopcontrolisstillrequiredtomaketheelectromagneticinjectoraccordingtothepresetenrichmentmixingTheairratioworkstogivefullplaytothepowerperformanceoftheengine,soacontrolmethodcombiningopenloopandclosedloopisadopted.

Dieselengineinjectionsystem

Classification

SincethefirstdieselenginewasinventedbyGermanDieselin1897,thedieselenginecombustionsystemhasundergonegreatchanges.Thefuelsupplysystemhasevolvedfromatraditionalmechanicalpump-tube-nozzletypepositioncontrolmethodtoanelectroniccontrolmethod,andhasdevelopedintoapump-tube-nozzletypeorpumpnozzletimepressurecontrolmethod.Themaximuminjectionpressurehasbeenincreasedfromthetraditional20-24MPatoover200MPa.Accordingtostructuralcharacteristics,itcanbeclassifiedintopump-pipe-nozzlesystem(includingsyntheticpumpsystem,distributionpumpsystemandunitpumpsystem),pump-nozzlesystemandcommonrailsystem.

Typicalsystem

1.Mechanicalinlineplungerpump

Theinlineplungerpumpisgenerallydrivenbythetiminggearofthecrankshaftofthedieselengine.Thepistontypefueltransferpumpfixedonthefuelinjectionpumpbodyisdrivenbythecamshaftofthefuelinjectionpump.Whenthedieselengineisworking,thefueltransferpumpsucksthedieselfromthedieseltank,removesthemoistureinthedieselthroughtheoil-waterseparator,thenfilterstheimpuritiesinthedieselthroughthedieselfilter,andthensendsittothefuelinjectionpump.Afterthedieselfuelinthefuelinjectionpumpispressurizedandmetered,itisfedintothefuelinjectorthroughthehigh-pressurefuelpipe,andthedieselfuelisinjectedintothecombustionchamberatacertainpressurethroughthefuelinjector.

2,pumpnozzle

Theelectronicallycontrolledpumpnozzleinjectionsystemisadieselfuelinjectionsystemthatcombinesaplungerandinjectorassemblyinashell.Itismainlycomposedofpumpnozzlebody,controlvalveandsolenoidvalve.Itisequivalenttocancelingthehigh-pressureoilpipeinthemechanicalpump-pipe-nozzlesystem,andaspecialcamshaftneedstobesetonthecylinderheadtodirectlydrivethetappettocontrolthepumpingprocessoftheplungerpump.Becausethereisnohigh-pressurefuelpipe,thehigh-pressurefuelproducedbytheplungerpumpdirectlyentersthepressure-bearingringgrooveofthefuelinjector.Thefuelinjectiontimingandfuelinjectionvolumearecontrolledbythehigh-frequencysolenoidvalvetocontroltheopeningtimeandtheopeningdurationofthefuelinletvalveofthepumpnozzle.

3.High-pressurecommonrail

CommonRailSystem(CommonRailSystem,CRS)isahigh-pressurefuelinjectionsystempursuedinthefuture.Thegenerationoffuelpressureandinjectionareseparated.Thefuelinjectedintoeachcylindercomesfromacommonpressureaccumulatorthatalwaysmaintainsahighpressure.Thefuelpressureoftheaccumulatorisgeneratedbythehigh-pressureradialpistonpumpandcanbechangedwiththeworkingconditionsoftheengine.Eachcylinderheadisequippedwithaninjectorcontrolledbyasolenoidvalve.Thefuelinjectionquantityisdeterminedbytheexitsectionofthefuelinjector,theopeningdurationofthesolenoidvalveandthefuelpressureintheaccumulator.Thepressureoftheaccumulatorfuelinjectionsystemcanbeashighas180MPa.Thefuelpressuretargetofthefuturesystemwillbehigherthan200MPa.Thestartoffuelinjection,pre-injectionandpost-injectionarecontrolledbyfastsolenoidvalvesorveryshortpiezoelectricelementswithacontroltimeoflessthan100µs.Theinjectionvolumecanbelessthan1ml.